What are the advantages of Re-Use Systems?

Aquaculture reuse systems or partial recirculation systems (PRAS), more recently called hybrid flow through systems (HFTS), are not new, but have been around for decades. They differ from flow through in that most of the water is recycled, but they also differ from recirculation systems (RAS) in that there is enough water exchange to flush dissolved nutrients eliminating the need for a biofilter. This considerably reduces complexity while saving water flow.

They are a logical improvement for existing flow through farms that need to reduce water use for various reasons including:

Water supply has become limiting.

The farm needs to grow and there is no additional water flow available.

The farm needs to comply with stricter regulations regarding water use or discharge

The intake water needs to be filtered and/or sterilized to improve biosecurity. It is more economical to treat smaller flows required for PRAS than flow through. PRAS use much less water than flow through. Typically PRAS might use one exchange per day in contrast to flow through which may use 18 to 24 exchanges per day (100% vs 1800% or 2400%).

Example:

A trout farm has 48 raceways, 100 ft long, 12ft wide, 3ft deep. Total volume = 172800 Cuft

At 18 exchanges per day, the flow rate required would be:

36 CFS or 16,157 GPM

If we install a PRAS on this farm, we can reduce the demand to around one exchange per day (depending on ambient temperature profiles at the site) so that the required flow rate is now:

2 CFS or 898 GPM.

In other words, the farm would require 1/18 of the water, or if space was available to expand the farm, the production could be increased 18 times with the same water flow.

What do reuse systems do?

PRAS are designed to:

Remove solids

Remove CO 2

Re-oxygenate the water

Return the filtered oxygenated water to the top of the farm.

Solids Removal

The drum filter is the usual workhorse for solids removal in a PRAS. Aquacare supplies Faivre stainless steel drum filters to the US and Canadian industry. After decades in service, these filters have proven themselves reliable and efficient. The solids removed by the drum filter are comprised of fecal waste and uneaten feed. This is concentrated in the backwash, which can be directed to a retention pond or settlement tanks for further processing or removed off site where it may be used as agricultural fertilizer. Since this flow is a fraction of the normal flow that would go to the retention pond or settling tanks, these can be much more effective or downsized.

RE-USE SYSTEMS

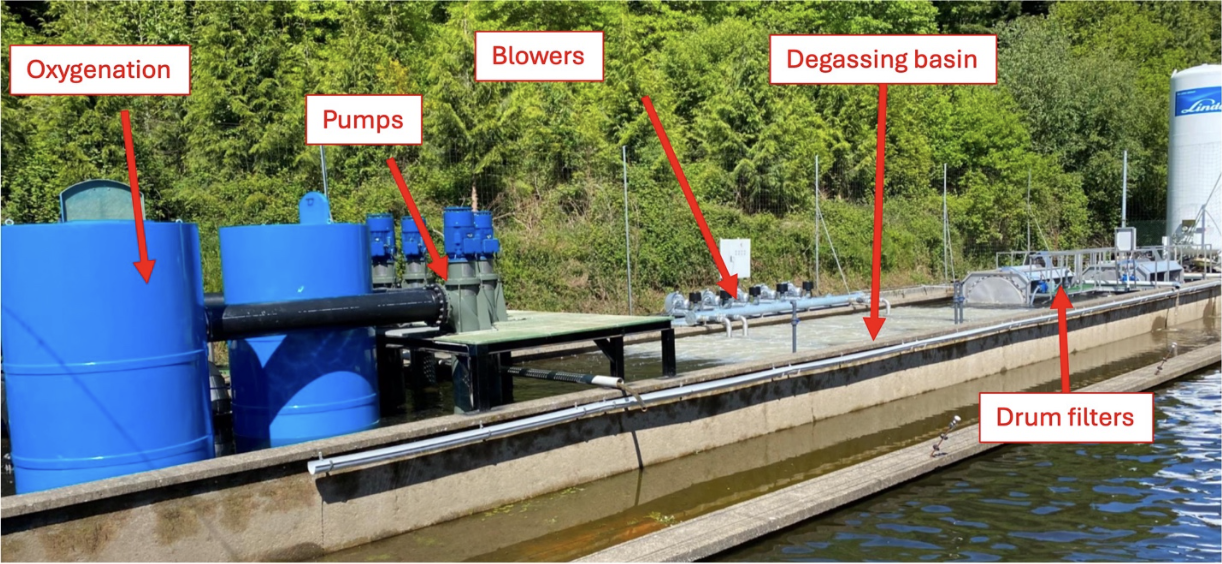

Several drum filters in parallel on a large trout farm

CO 2 removal

We recommend two different approaches to degassing: shallow diffuser basins or forced air stripping columns with structured media. Degassing basins require more space, but columns require more pumping. The choice between the two depends on the site conditions. On trout farms using raceways we will often recommend converting part of a raceway to a degassing basin to save costs.

Shallow degassing basin installed in part of a fish raceway.

Oygenation

Aquacare has been in business since 1987 and we have seen most types of oxygenation solutions for aquaculture including pressure packed columns (PPC), U-tubes, oxygen cones, in-line diffusers and low head oxygenators (LHO). None of these really compete with the Oxyflow® in efficiency or power consumption. Oxyflow® or Oxyfox® technology has been deployed on dozens of trout farms in Europe where PRAS have been installed. Some of the original units are more than 30 years old and still in use.

Very often we see that the first response to low oxygen on trout farms limited by flow is to use pure oxygen with diffusers. While this is a good back up in the case of an emergency such as a power outage, this type of oxygenation is tremendously inefficient (around 25%) and regular use will mean a large amount of money literally blowing away.

Pumping

Once the water is filtered, the CO 2 is stripped out, and the dissolved oxygen is replenished, the water is returned to the fish. In a typical trout farm using raceways, this water is re-introduced at the head flume. This should be done without splashing to prevent the loss of dissolved oxygen and should be combined with the new water coming from the source. We supply highly efficient turbine or axial flow low head/high flow pumps for this purpose.

Contact us with your ideas and projects. We can help you design a new system, supply high quality reliable equipment for an existing design or troubleshoot and improve or upgrade a system that you already have.